Nominal settings: These are the

"nominal" settings for the supplies, when you don't want any of the

heaters on. Do this with

the outputs

OFF so that you

can see the limits, not the actual values. Once you have made the

settings, you should hit the

OUTPUT

button to turn the outputs

ON.

It's actually not too important to set these nominal values anymore; as

of April, 2004, the fridge control program initializes all the supplies

(except the JFET supply) as necessary at the start of the cycle.

Enabling

front panel control: The

LOCAL

button makes it possible to control the supply using the front panel;

if the supply is not in

LOCAL

mode, the front panel is locked out and the supply is controlled by

GPIB. You can feel free to press the

LOCAL button at any time, even

during a fridge cycle -- the fridge computer can still control the

supplies. If the

power supplies do not appear to be responding even after pressing the

LOCAL button, it may be because the

fridge_cycle

program is simultaneously trying to read them. Set the sample

rate on

fridge_cycle to some

relatively large value (less than 1 per minute) and then attempt to

program the supplies. Set the sample rate for

fridge_cycle

back to its original value afterward.

Enabling

the outputs: There is an

OUTPUT

button that enables/disables

the outputs. The

OUTPUT

button controls relays that actually connect the internal

supplies to the output banana jacks. Thus, even if you have set

the output currents and voltages, they won't actually be activated

until the

OUTPUT button has

been pressed. Conversely, if the output currents and or voltages

are set to 0, then pressing the

OUTPUT

button will not do anything except energize the relay; current will not

necessarily flow. On the display, in the upper right corner,

there is an

OUT light that

will be on if the outputs are enabled (1st row, 4th column in matrix of

status lights).

How to

select which channel is displayed: To set which

output is displayed/controlled via the keypad: find the keys that say

OUT1,

OUT2,

OUT3 in light blue above them.

Press the

SHIFT button and

then press whichever of these buttons corresponds to the output you

want to display/control. Note that the supply must be in

LOCAL mode for these (or any other)

buttons to work. The first column of the matrix of status lights

has three lights indicating which supply is being displayed.

How the displays work: The displays do

different things depending on what state the supply is in. When

the outputs are off (

OUT light

off), then the displayed current and voltage are the values that have

been set (see

To set outputs currents and

voltages below). When the outputs are on (

OUT light on), then what is shown

is the actual current and voltage. What these are depends on the

settings. Though you set a current and a voltage, the supply

can't necessarily satisfy both of these settings. It picks the

"lower" one. For example, if you set 50 mA and 35 V for the UC

pump heater, which has a total resistance (including leads) of maybe

250 ohms, then you will see 0.050 A and 12.5 V on the display because

50 mA x 250 ohms = 12.5 V < 35 V. The current and voltage

settings thus act in some sense as limits for each other.

To set output currents and voltages:

- Select the output you want.

- On the numeric keypad are CURRENT

SET and VOLTS SET

buttons. Press the one you want.

- Enter the value you want to set using the buttons, e.g., for 35

mA, hit 0 . 0 3 5 followed by

the enter button, which is an arrow with a right angle in it.

- What you see on the display will depend on whether the outputs or

on or off -- see How the displays work above.

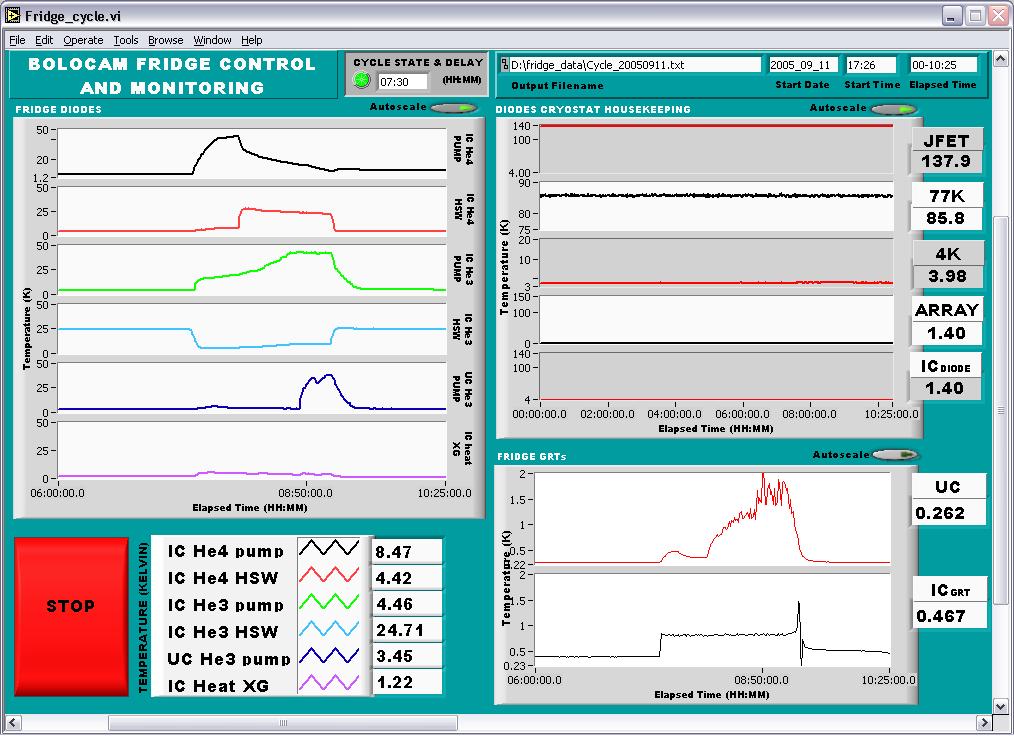

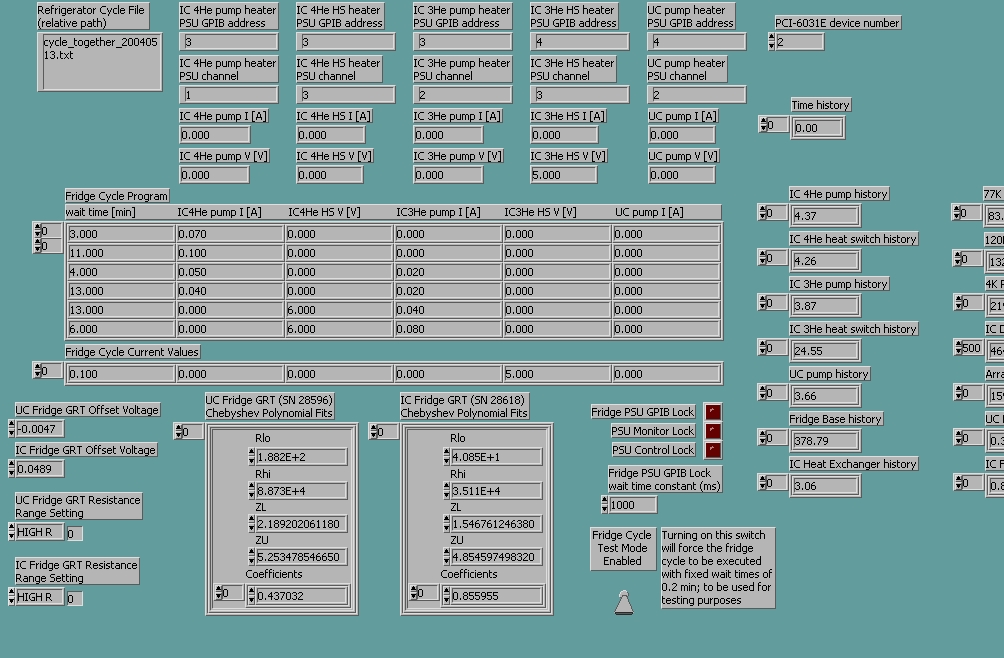

There is now a program for direct

control of the power supplies

available on the DAS computer. Go to the desktop of the DAS

computer,

open the shortcut to the FRIDGE

folder, and double-click on ManualPSUControl.

Hit the arrow in the upper left corner to start the program. The

bottom two rows of displays indicate the current power supply

settings. Set the middle two rows of controls to the desired

settings. Note that you must set all

the controls appropriately, even the ones you don't want to change;

when the program commands the power supplies, it sets all of the

control values. When you are ready to issue the command, press

the

button on the left side of the panel that says "Press to set PSU

values". The bottom two rows of displays should then update to

reflect

your new settings. If you have problems, press the Reset button

in the

upper left and try setting the power supply values again.

Note that the current and voltage indicators show the actual currents and voltages, not

the programmed ones.

There may be interference of this program with the standard fridge

cycle program if they try to communicate simultaneously with the fridge

power supplies. To avoid such interference, set the fridge

control program to a slow sampling rate (1 per minute or slower) before starting ManualPSUControl,

and then do your manual commands in the interval between samplings by fridge_cycle,

and then stop ManualPSUControl.

If the programs seem to interfere (very slow reading of supply

settings, nonsense or mixed-up values), then just kill ManualPSUControl

using the red stop-sign button in the upper left of the screen and try

again. Note that the normal stop button on the front panel of ManualPSUControl

will not work if it is hung in the communication cycle.