llegr

Bolocam Web Page: Setting up for Observing

Setting up for Observing

- Summary and

Planning

- Glossary

- Orientation and

Directions

- Mirror Installation

- Rotator Installation

and Removal

- Optics Box

Installation and Removal

- Optical Alignment

- Dewar

Installation/Removal

- Moving the dewar down

to the alidade

- Mounting the dewar on

the optics box

- Cabling Setup

- Rotator Electronics

Setup and Cabling

- Telescope Interface

Cabling

- Physical Routing of

Cables

- Electronics Setup

- Revision History

Back to BolocamWebPage

Back to ExpertManual

Summary and Planning

At least in the near term, it will be necessary to mount Bolocam from

scratch on the day that observing begins -- usually another instrument

has been in use at the Cass focus up until the night before run

start. This procedure takes essentially all day, from about 9 am

to usually 6 or 7 pm. Plan your manpower accordingly. The

overall order of the steps for mounting, along with the persons who are

usually responsible, are:

- Dismount previous Cass focus instrument (day crew)

- Mount Bolocam optics box at Cass focus (day crew)

- Bring Bolocam and dewar cart down to alidade platform (day crew +

instrument team)

- Test mount Bolocam to optics box (instrument team)

- Start fridge cycle with Bolocam on cart on alidade (instrument

team)

- Align Bolocam optics (instrument team)

- Mount Bolocam and set up all cabling (instrument team)

Items 1. and 2. can be done by the day crew alone, so the instrument

team members need not even be at the summit for these steps.

Depending on which instrument was at the Cass focus prior to Bolocam,

these steps are usually done by 10 am or 11 am; consult with the day

crew on this.

Any necessary preparation of the optics box should be done prior to the

instrument switch day. This includes

- installing any mirrors that

may have been removed (should not be necessary now that SuZIE uses our

optics)

- installation of our rotator and rotator plate (only necessary

if SuZIE has used the optics box between our runs)

- touching up the

eccosorb

- taking off the right side circle panels and the front and

back side panels in order to allow access for alignment

- installation

of any panels that can be in place during optical alignment

- making

sure you've found all the plates, turnbuckles, bolts, and alignment

tools

Do everything possible before the day of the instrument

switch, as you already have plenty to do on that day!

In terms of fridge cycling, what we usually do is to hold off on the

fridge cycle until the dewar has been moved down to the alidade and a

test mount to the optics box has been done. The fridge cycle can

then occur while the optics box is being aligned and cables are

being routed over from the racks on the third floor. It is

necessary to wait until the end of the cycle to mount the dewar

onto the optics box. One could in theory do the cycle in the

morning before bringing the dewar down, but one might reduce the hold

time with all the jostling during moving of the dewar.

In terms of cryogen fills, it is best to do a LHe fill while the dewar

is still on the 3rd floor, and then do both LN and LHe after the dewar

is in its final position on the optics box. The LHe is needed for

the fridge cycle, while adding LN early will just unnecessarily

increase the weight of the dewar.

Glossary

- access panels: the

circular panels attached to the side of the optics box that allow

access to the inside of the box.

- black plate: the

black-anodized steel plate used to mount the optics box to the

telescope. It has a large circular hole in it, the same size as

the large circular hole on the optics box input-side face.

- black frame: the black

steel frame permanently attached to the telescope that the black plate

mounts to

- rotator: refers to the

cylindrical rotator assembly; there are two pieces, the piece that

mounts to the box and the piece that the dewar sits on. They are

held together by a bearing, allowing them to rotate relative to one

another.

- rotator plate: the plate

that attaches to the optics box and accepts the rotator. It has a

large circular hole in it, and some markings where the rotator

electronics mount.

- side blocks: the blocks

on the two sides of the optics box that are used to control the

position of the tilt axis of the Bolocam tertiary mirror mount

- telescope stop button or stop button or stop: large red buttons distributed

around the telescope (1st floor apron, alidade platform, control room,

4th floor near crane) that cut the power to the telescope and dome

drive. These should be pushed in when you are doing work that

requires the telescope remain stationary; you never know what the drive

motors could do!

- tertiary mirror: the

small ellipsoidal mirror that serves as an optical relay to the sidecab

instruments. It's on a flip mount so that it can be folded out of

the way for Cass focus observations. We will also refer to the

Bolocam ellipsoidal mirror in the optics box as the tertiary mirror; in

general, context will prevent confusion. The modifiers "CSO" and

"Bolocam" will be used to distinguish the two where confusion may arise.

- tertiary mirror mount:

the large flat plate that the Bolocam tertiary mirror is bolted

to. This mount has many degrees of freedom, described below.

- tertiary mirror stop:

this is a funny-shaped piece of metal that serves as a stop to fix the

position of the CSO tertiary mirror.

- tilt-axis push-pull screws:

these are the two screws at the corner of the Bolocam tertiary that

allow you

to control its rotation angle about the Bolocam tertiary mount tilt

axis.

- worm gear: the large

screw jacketed in a black bellows on the left side of the alidade

platform. It drives the elevation motion of the telescope.

Orientation and

Directions

- The front of the

optics box is the end that the light enters through; i.e., the end with

the circular hole.

- The back

is where the rotator and dewar mount.

- Right and left assume that you are standing

behind the optics box, looking toward the front of it. To be

clear, when mounted, the worm gear is on the left side of the box and

the alidade stop button is on the right side.

- Down and up are usually only used from the

point of view of someone standing behind the box, and refer to down to

the floor and up to the dish.

- Clockwise

and counterclockwise assume

that you are again standing behind the box looking down the optical

axis (time-reversed sense).

Mirror Installation

Rotator Installation

and Removal

It is up to you whether you want to install the rotator before or after

the optics box has been attached to the telescope. It tends to

unbalance the optics box weight a bit and so makes it harder to lift

down to the alidade and install, but getting it on beforehand saves

about 30 minutes so is certainly worthwhile.

Here's a picture of the optics box

with the rotator installed.

If the homing sensor and limit switch have already been installed, be

careful to avoid damaging them!

Installing the rotator is trivial, but takes 3 people due to its

weight. You can get away with 2, but 3 makes it easier. The two

lifters can't be 90-pound weaklings. Remember, lift with your legs, not your

back! Here are the steps:

- Make sure the correct rotator

plate is in place on the optics box; the Bolocam plate is

heftier than the SuZIE plate and has a flat milled region that the

rotator mates to. There is only one way that the plate can fit on

the optics box.

- Bring the rotator behind the optics box, rotating it so the motor

mount points due right.

- Check that four surfaces are clean: the mating surface on the

rotator plate, the mating flange on the rotator, the curved flange down

inside the optics box that the bottom of the rotator will rest on, and

the bottom of the rotator. Clean any other crud off the rotator

so it doesn't end up on the optics.

- The two people doing the lifting should stand on the right and

left sides of the rotator. The third person (who doesn't need to

be particularly strong) should stand behind the rotator.

- The two lifters should grab the rotator at the top flange (the

one that mates to the dewar), lift the rotator straight up and then

over the rotator plate hole. Think ahead of time about how high

the rotator will have to be lifted and set your grip accordingly.

- The third person should push the bottom of the rotator from

behind so it tilts and goes into the rotator plate hole.

- As the rotator drops in, it usually hangs up; the third person

just needs to provide more tilt.

- Once the rotator has dropped into place, it is stable (i.e., the

lifters can let go). Rotate the mating flange so it lines up with

the large bolt holes in the rotator plate and screw it in. Again,

make sure the motor mount points due right

before you screw in.

Removal is also easy, just reverse the above steps. Screw the

rotator-rotator plate mating bolts back into the rotator plate so they

don't get lost.

Attaching the motor and belt:

- The motor sits in an aluminum mounting frame that mates in an

obvious manner to 8 large bolt holes on the side of the rotator; see

the picture. A minor

problem is that

the threaded holes in the rotator are drilled radially while the

through holes in the motor mount are drill vertically, so it's

difficult to get some of the screws in. You should be able to get

enough screws in to ensure stability.

- On the upper end of the motor frame, next to the gear, there is a

slot for the pulley; see the picture

to see

how this should look when installed. The pulley can slide toward

and away from the rotator; it is used to take up slack in the rotator

belt. The pulley is fixed in place by tightening the shoulder

bolt that goes through the center of the pulley (there is a special nut

on the bottom of the plate that accepts the shoulder bolt). In

theory the shoulder bolt (because it has a shoulder) should allow the

pulley to freely rotate. In practice, the pulley gets a little

tight, but it's ok, the belt can slide on the pulley anyways and the

motor has enough torque to put up with the extra friction.

- The belt is attached to the rotator using two clamps. The

clamps have dowel pins sticking out their bottom sides that mate to the

belt, preventing the belt from slipping once the clamps are

installed. There is some freedom as to how to install the clamps

-- there are multiple pairs of mounting holes and the clamps can be put

on in one of two orientations. Use the maximally separated set of

mounting holes; the clamp orientation doesn't matter too much, but try

to choose it to minimize the slack in the belt. See the picture

for a view of the clamp positions and how the belt looks when

installed. Use the limit switch tab (the thing sticking downward

from the dewar mounting flange) as a reference point. Note that

you should mesh the belt with the gear during this process to get the

clamp placement right.

- Slide the pulley to take up any remaining slack in the belt.

Attaching the homing tab and sensor, limit switch, and encoder:

- The homing sensor is a small IR

sensor with a slot in it that

senses when the homing tab passes through it. The sensor attaches

to the stationary part of the rotator, just below the belt.

There's some freedom in the mounting, don't worry too much about it.

- The homing tab is just a small, bent piece of sheet metal that is

attached to the rotating part of the rotator with a small clamp similar

to the belt clamps. You can see it in this picture, it is under the free loop

in the belt between the two belt clamps. You will have to tweak

so it passes cleanly through the slot in the homing sensor.

- The limit switch sits just to the

left of the motor mount.

Note that the mounting screws are different sizes and not all of them

go in! Just make sure it is stable. If necessary, adjust

the length of the switch shaft so it will be pushed by the limit switch

tab (a small aluminum right-angle tab attached to the bottom side of

the dewar mounting flange). Try rotating the rotator and making

sure the tab trips the switch but that the switch shaft otherwise does

not interfere with the motion of the rotator.

- The encoder attaches to the two slotted holes near the pulley;

see the picture. The

attachment is

obvious. The encoder should be adjusted so that the gear on its

shaft meshes well with the gear on the rotator.

Optics Box

Installation and Removal

The day crew are really the experts on this; they will drop the optics

box onto the alidade, wheel it into position, and then

lift it up and bolt it to the telescope frame at its front end. A

couple of useful bits of information or things to watch out for:

- The optics box mates to the telescope via the black plate. This plate is

attached first to the black frame

that is permanently fixed to the telescope, and then the face of the

box with the large circular hole is bolted to it. The instrument

team should check that all the parts are easily available (i.e., make

sure the you find the black plate, also dig up the screws if possible)

so that this can be done easily.

- In addition to the black plate interface, there are two

turnbuckles that attach to the optics box just ahead of the

rotator. Find these ahead of time also. The day crew will

usually install them for you, but you should check they are

tight. They will be adjusted during optical alignment.

- It is easier if you clear out any obstructions near the black

frame ahead of time, though you can usually get access after the box

has been installed. Especially, remove the CSO tertiary mirror

stop

(put the parts on the shelf on the alidade so they are easily found!)

and make sure the CSO tertiary mirror is out of the way. If you

are

multiplexing with the heterodyne receivers, make sure you know where

you have put the parts as they will need to be reinstalled for

heterodyne observing.

- Remember to remove the front panel of the optics box (nearest the

first flat mirror) before the optics box is mounted -- having the front

panel open will make it easier to do the optical alignment. It is

easier to remove before the box is mounted, but can be done

afterward. You will have to reattach the panel with the optics

box mounted by crawling back behind the box. It is doable.

Similarly, the day crew will take care of removal of the optics box

once the dewar has been dismounted and is out of the way.

Optical Alignment

The general strategy is to make use of the telescope as the reference

surface and align relative to it. You will first level the box,

then dead-reckon align the two flats, then laser align the

tertiary. Make sure the front and back plates and right side

access panels are off so you can put the level on the mirrors.

- Level the optics box

- Start with the telescope tilted to ZA = 4 degrees. This

is

usually the position that the telescope is in when the optics box is

mounted to it. Hit the telescope stop button on the alidade

platform.

- Zero out the digital level on the black frame. Be careful to

hold

the level flush to a surface so that you are sure it is perpendicular

to the ZA direction (the front-back direction); the slight ZA tilt can

cause errors in your zeroing if you are not careful.

- Level the optics box using the turnbuckles. Place the

digital level on the optics box input plate (the one mating to the

black plate), using some piece of the box to make sure the level is

perpendicular to the ZA direction. Adjust the turnbuckles until

they are tight and the box is level in the left-right direction.

They must be tight or the box will move when the dewar is attached.

- Check the front-back tilt of the box. Rotate the digital

level so it points along the front-back direction. The level

should read an angle equal to the current ZA. Record the number

for later reference.

- Align the flat mirrors:

- Release the alidade stop button, move the telescope to ZA =

26.19 degrees, and hit the stop button again. This is the angle

that the two flat mirrors will

be tilted relative to the optics box. By tilting the telescope,

all you have to do is level the mirrors, which is much easier than

setting to 26.19 degrees in one direction and leveling in the other.

- Level the flat mirrors. Set the level down on the center

of

the mirror, aligned with the direction you want to level. Each

mirror has 4 screws accessible through the optics box cover plates via

hex-head T-drivers. I think the driver needed is 9/64", though

this should be confirmed. The screws are "pull" screws -- when

tightened, they pull on the section of the mirror mount to which they

are attached. So, to change the mirror tilt along a given

direction, you have to tighten one and loosen the other of the two

screws along that axis. You should be able to level to roughly

the readout precision of the level (0.1 degrees). Check the

leveling at multiple places on the mirror; you will get 0.1 to 0.2

degree variations, but not more than that. As you are leveling,

make sure the screws are nice and tight; you don't want the mirror to

move around as the optics box tilts.

- Align the Bolocam tertiary. You have dead reckoned the

flat mirrors, so now the idea is to send a laser beam out along the

optical axis and look for its spot on the secondary, tweaking the

tertiary until the laser is centered on the secondary.

- Release the alidade stop button, tilt the telescope to ZA = 10

degrees or so, close the dome so you can see the laser, and hit the

stop button again. The slight

ZA tilt will make it easier to get at the tertiary adjustment screws,

which are accessible via holes in the bottom of the box using T-drivers.

- Install the laser jig on the rotator. By feel, you can

get the top plate of the laser jig well centered on the rotator; put in

3 bolts from the bottom side of the rotator to hold it in place.

- If the laser is not already attached and centered on the jig,

do so now. The laser sits in the V-block and is clamped by two

screw clamps. The V-block is well-centered transversely but can

slide along its long axis (there are screws to tighten it in

place). There are pre-aligned holes in the top and bottom plates

that the laser will shine through; use these to adjust the V-block so

that the beam is shining nicely through both holes. This ensures

the laser is aligned with the jig. To turn on the laser, just

screw down the endcap (it makes contact to the batteries inside and

completes the circuit).

- To determine whether the laser is aligned with the rotation

axis of the rotator, just rotate the rotator and watch the spot on the

tertiary. (Turn off the motor and/or remove the belt

to make this easy to do.) When the laser is aligned with the

rotator, the spot will not move as you rotate the rotator. If

there is misalignment, the spot will describe a circle on the tertiary

whose radius is the misalignment between the laser and the rotator

axis. (Note that the construction of the laser jig ensures that

the laser beam is at least parallel to the rotator axis to good

precision. All you have to worry about is tranverse displacement.)

- Now that you have the laser fully set up, you will adjust the

tertiary. The tertiary has multiple (too many!)

adjustments. On the sides of the optics box, you will see metal

blocks whose position is set by 4 screws (the side blocks). These blocks are

attached to the tilt axis of the tertiary mirror mount. Each

blocks can move in a plane, and the two blocks move independently, so

you have a lot of freedom to move the tertiary tilt axis. Once

these are fixed, you control the tilt of the tertiary around this

rotation axis using push pull screws at the back right corner of the

tertiary mount (the aptly named tilt-axis

push-pull screws); access to these screws is through two holes

in the bottom of the box, you will need T-drivers to get to the screws.

There is fundamentally no great way to do the adjustment. Some

degrees of freedom are degenerate, and many degrees of freedom that are

nominally independent are not really so. The process is

inevitably iterative. Some general suggestions:

- Put one person on each side of the box (one on each side

block) and one person sitting on top of the hex plate looking at the

secondary. The easiest way to get to the left side of the box is

to lie down on the alidade and pull yourself under the box to the left

side so you are sitting next to the worm gear. The right side

block person will also adjust the tilt-axis push-pull screws.

- The person looking at the secondary will be tempted to look

back down into the optics box; of course, make sure that person doesn't

end up looking down the laser beam!

- Do whatever is necessary to get the laser beam on the

secondary to start with. You have to start somewhere.

- Try to do the adjustment to get the mirror as far forward as

possible -- there have been occasions where we get the laser

satisfactorily aligned and then realize the mirror is so far back that

one cannot put the back panel on the box.

- Start with the left-right adjustment by getting the tilt of

the tilt axis correct. That is, the tilt axis ought to be

perpendicular to the sides of the box so that, when you work the

tilt-axis push pull screws, the beam only moves along the elevation

direction on the secondary. You don't want tilting of the

tertiary to cause the spot to move diagonally or transversely across

the secondary, it will cause you great misery later.

- There are always degeneracies. Even when you've got the

tilt axis squared up, there is probably a degeneracy between moving the

tilt axis and the mirror tilt angle. There's nothing you can do

about it. If the optical axis hits the wrong spot on the

tertiary, it can be for the most part corrected with the secondary

focus parameter.

- Don't get too worried about whether you are hitting the right

spot on the tertiary (if you even know where that spot is!). We

in fact demonstrated to ourselves that it is physically impossible to

hit the design spot on the tertiary and not have the mirror stick out

the back of the box. Someday we will figure out what is going on,

it's not your problem.

- Once you are happy with the alignment, tighten down all

screws. Be careful to avoid damage to any of the screws by

overtightening, or warping of the mirror mount.

- Do a check on the variation of the alignment with telescope

elevation. The person watching the spot on the secondary should

harness himself into the telescope backstructure (there are usually

harnesses in the lockers on the first floor of the dome) and ride the

telescope as one goes from ZA = 10 to ZA = 60 and back again, watching

the position of the spot as the ZA changes. There will always be

some motion, but you want it to be a small fraction of the size of the

secondary. We don't have a hard and fast spec on this, you mainly

want to make sure everything is nice and tight and there is no extreme

motion of the beam because something that should be tightened down is

not.

- Finally, remove the laser jig from the rotator, remove the

batteries from the laser and tape them to the jig, and put the jig away

in the 3rd floor lab where the rest of the Bolocam equipment is

stored. Store the digital level with the laser alignment

jig. It's very important to not lose the level or the jigs, they

are unique and trying to do the alignment with kludgey replacements is

very difficult!

Dewar

Installation/Removal

This is the part that usually inspires fear -- getting the dewar down

to the alidade platform and onto the optics box. There are two

steps: getting the dewar down to the alidade and situated on its cart

there, and then mounting the dewar on the optics box.

Moving the dewar down

to the alidade

You will remove the dewar from its cart with the crane, leave it

suspended on the crane while you move the cart down to the alidade, and

then drop the dewar down to the alidade and reattach it to its

cart. If you have trouble remembering how to deal with the

dewar straps and buckles, refer to the Messing with the Innards page.

- Put the window cap on the dewar

-- you do not want to accidentally puncture the window during any of

the following steps!

- If you have not already, do a LHe fill. Do not do a LN fill

unless you did not do one the day before.

- Remove the electronics box. This will of course require

turning off the power and disconnecting all cabling. See the Electronics page for instructions on doing

this.

- Screw the dewar eyebolts into the 4 threaded holes on the top of

the dewar (the same holes that accept the support legs). These

eyebolts are usually stored with the dewar screws.

- Wheel the dewar over to where one can access it with the

crane. The day crew will rig the dewar to the crane using the

eyebolts. Slowly take up the weight of the dewar with the

crane. When you are confident the rigging is solid, release the

dewar straps so that the dewar comes free of the dewar holder and

cart.

Leave the dewar hanging from the crane (lower it down close to the

floor so it doesn't have far to fall if something happens!).

- Disassemble the cart. Check that the cotter pin that

prevents rotation of the dewar holder is in place. The dewar

holder is attached to the cart with two aluminum rods on the back held

in place with cotter pins; you will have to remove these rods to free

the dewar holder. You have to take the weight off the rods to get

them out, but the holder is very heavy. Lower it down to a height

where one person can get a good grip on it (lifting with the legs, not

the back!) and then one other person can pull the cotter pins and

rods. Once the dewar holder is off, pull the cart legs out.

They are held in by

spring-loaded pins. Sometimes you have to tilt the cart back a

bit to get the weight off the legs. Finally, remove the crank

(also held in place by a spring-loaded pin).

- Take the pieces down to the alidade. The cart is the

hardest part; we usually drop it down over the side directly to the

alidade, see the picture.

Remember, it's heavy and wants to catch on the red rail.

- Reassemble the cart on a large rectangular dolly on the alidade

so that it can be used to lift the dewar onto the optics box.

The orientation of the dewar on the cart is important, so we provide

some pictures of the mounting of the dewar onto the optics box to give

you a better idea: picture

1, picture 2, picture 3. As you

can see, the cart must be oriented a certain way to tilt the dewar so

that is can be mounted on the rotator, but this orientation is

incompatible with moving the cart toward the optics box as the dewar is

eased into place because it is transverse to the normal direction of

motion of the car. Hence the dolly -- it allows the cart to move

as needed. Note the orientation of the dolly on the alidade

platform, the orientation of the dewar cart on the dolly, and how the

cart must be placed to align the dewar with the rotator. See the picture

to see what your end result should be.

We usually use one of the dollies that are used for storing instruments

up on the third floor. Orient the dolly on the alidade so that

its long axis is transverse to the platform (going left-right).

Put the cart on the dolly and attach the legs. Position the cart

on the dolly so that when the dolly is pushed toward the optics box,

the dewar cart will hold the dewar in a position such that it can be

aligned with the rotator. And of course make sure the cart is

placed so that the dolly won't tip when the dewar is placed on

it! Clamp the cart into place using 2x4's screwed into the dolly;

see picture 1 and picture

2. It's hard to see in the picture but there are 2x4's along

both the legs and the along the main section of the cart; the cart is

completely immobilized.

Finally, reattach the dewar holder to the cart. This is a bit

difficult because of its weight. Again, use one person to carry

the weight of the holder and 1 or 2 others to get the aluminum rods in

and insert the cotter pins. Make sure the holder is oriented as

indicated in the picture.

- Bring the dewar down and reattach to the cart. The travel

of the crane prevents you from bringing the dewar down into the most

convenient place; the dewar usually ends up on the right half of the

alidade, so you have to rotate the dewar cart around to mate to

it. See picture 1 and

picture 2 to get an idea

of where the dewar sits when the crane lowers it to the alidade, though

note that 1) we no longer leave the e-box and dewar holder attached to

the dewar when moving it; and 2) depending on the length of your dolly,

you may have to rotate it 90 degrees to bring the cart close enough to

the dewar. Once you have the dewar close enough to the cart, you

can strap it into the dewar holder in the usual manner. Remember

to get the orientation of the dewar holder correct and to use the

correct slot in the holder to grab the dewar's middle flange; see the picture. Make sure to get the

azimuthal rotation angle of the dewar correct; the bath exhaust ports

should point back toward the cart. If you do not get close

enough, you will not be able to tilt the dewar properly for the fridge

cycle.

- If you want to do a test fit to the optics box (e.g., to make

sure you have mounted the cart onto the dolly correctly), you can do so

now; basically, just follow the directions below for attaching the

dewar to the optics box, except you don't need to bother with the

spacer and you can quit once you get close enough that it is clear the

dewar will mate properly.

- Reattach the e-box, recable it, and power up; see the Electronics page for instructions on doing

this. In routing the cables, think about how the cart will have

to be oriented during the mounting process and route the cables so they

will not interfere. This usually means they should go toward the

back of the alidade.

- At this point, you should tilt the dewar and start the fridge

cycle, and then start doing the optical alignment.

Mounting the dewar on

the optics box

This is really not that hard. You just have to make sure you get

the orientation right. Look at these pictures to get an idea of

how it will look: picture

1, picture

2, picture

3. See also how the dewar looks when finally mounted.

Remember that you have to wait until the fridge cycle is done because

the dewar must be rotated such that it is not tilted to the fridge

cycle position.

Preparations:

- You will need 0.75 inches of lucite electrical isolated/spacer

between the dewar and the rotator. This usually

means the specialized 0.25 inch spacer (which has shoulders to clear

the rotator encoder gear) and a simple 0.5 inch spacer. These

should be in the 3rd floor Bolocam storage room.

- You will also need the special dewar mounting bolts. These

are special long bolts with hex heads and, most importantly, nylon

shoulder washers and oversized metal washers. They should be in a

tupperware container with the laser alignment jig and the digital

level. The nylon washers are important for ensuring electrical

isolation between the dewar and the optics box, and the shoulder

washers prevent the bolt heads from biting into the nylon. Make

sure you understand how they all fit together: each bolt gets two nylon

and two oversized washers, with the shafts of the nylon washers

pointing toward each other and the oversized metal washers sitting on

the large flat part of the nylon washers.

- You will also need some freedom to rotate the rotator. If

the belt is not attached, then you are all set. If it is

attached, make sure the motor is off.

- Tilt the telescope to ZA = 4 degrees and hit the alidade stop

button.

- Make sure the dewar window cap

is on!

Mounting:

- Rotate the dewar so that it is in the correct orientation for

mounting. Rather than the bath exhaust lines pointing at the

cart,

they should point 90 degrees away, counterclockwise as viewed from the

top. See the mounting picture

for clarification. To do this, you have to loosen the dewar

straps 1-2 clicks and then rotate the dewar, taking up some of the

weight yourself to reduce the friction. Loosening the straps is

tricky: you have to release the buckle and let the strap slip 1-2

notches on the ratchet and then lock again. If you loosen too much, the dewar will fall

out of the cart! The bottom strap is noncritical right now

(the top strap is the one holding the dewar to the cart), so you can

use the bottom strap for practice. You should have two spotters:

one pushing up on the e-box (who will push the dewar back toward the

cart if you loosen too much) and one at the back of the cart (to

prevent if from sliding away when the other spotter pushes). Once

you have the straps loosened, the e-box spotter and the strap-loosener

can push up on the dewar (to take the weight off the straps) and rotate

it. Once the dewar has been rotated, retighten the straps.

- Rotate the dewar rotator into the correct position. There

is a label on the rotator that says something like "E-box points this

way". If you cannot find the label, the e-box should be between

90 and 120 degrees counterclockwise (as viewed from the top) away from

the rotator belt length takeup loop. See the picture. Rotate the rotator so

the e-box label points straight down; as indicated in the mounting picture, the e-box

itself will be pointing straight down when it is mounted onto the

optics box.

- Rotate the dewar cart around so that the e-box points toward the

back of the alidade, as in the mounting picture. Make sure

any cables are moved so they will not interfere with mounting.

- Remove the dewar holder cotter pin so you will be able to rotate

the dewar.

- Get your lucite spacers in place on top of the rotator. You

may need to use some tape to hold them in place until the snout is

inserted into the rotator barrel and can catch them.

- Now you will raise the dewar up, tilt it, and slowly ease the

dewar into place by alternately pushing toward the optics box, tilting

the dewar, and lowering the dewar until it can mate to the rotator.

When raising the dewar, note that the dewar cart actually lets you go

higher than you might think; the holder will run into the top of the

cart, and you will feel resistance from the crank, but if you keep

cranking, a second mast starts moving and the dewar will go

higher. Of course, don't go so high that the entire cart becomes

unstable.

Another problem you will run into is the worm gear -- in principle, one

would like to tilt the dewar 40 degrees (the angle that the rotator is

tilted to) raise it up so that the window is above the rotator, push it

toward the optics box, and then drop it in. The dewar will

probably run into the worm gear and prevent you from doing this.

So what you must do is tilt more than 40 degrees, push the dewar toward

the optics box to get the snout into the rotator a bit, lower the dewar

a bit, tilt back toward 40 degrees a bit, push toward the optics box a

bit, and so on until the snout is feeding into the rotator. The picture shows what

things look like midway through this process.

Trust me, it can be done! You just have to keep pushing, tilting,

lowering, etc., etc.

- Once you have the dewar snout very close to touching the lucite

spacers, get all your screw holes aligned. It is useful to stick

a bolt through the holes in the rotator and spacers and then into the

dewar flange. You may need ot rotate the rotator a little bit to

get the alignment.

- Continue to ease the dewar in so that its weight comes to rest on

the rotator. Get some bolts in, starting from the top side of the

rotator (toward the telescope). Remember,

you must insert the bolts from the bottom so the shafts do not stick

out and interfere with the rotator belt, and you must use the nylon

spacers and oversized washers! See the picture. It is dangerous to

stand

under the dewar at this point, so stick to the top side bolts for

now. You will find that you have to get a couple bolts in, ease

the dewar in a bit more, tighten up the bolts a little bit, ease the

dewar in more, etc. until the dewar surface is flush against the lucite

spacer.

- Continue to add bolts. You won't be able to get a few bolts

near the rotator motor right now, but do as many of the others as you

can. Tighten them up, taking care to adjust the dewar cart height

to make this easy.

- Once you are happy with the tightness of the bolts and the

stability of the dewar, start loosening the dewar straps to release the

dewar from the holder. Start with the bottom one, and then the

top one. Be careful to watch out for any signs that the bolts are

not taking up the weight of the dewar. Once the dewar is

completely free from the cart, pull the cart away.

- Rotate the dewar counterclockwise to get access to the bolts you

missed and install them. Tighten up all the bolts. Make

sure you are happy with the stability of the dewar.

- Tilt the telescope to ZA = 4 degrees and measure the optics box

tilt angle in both left-right and front-back directions by placing the

digital level on the plate with the large circular hole. The

left-right tilt should be 0 degrees and the front-back tilt should be 4

degrees. Compare the front-back tilt to that measured earlier

after tightening the turnbuckles and leveling the optics box without

the dewar attached.

Cabling Setup

This section discusses 3 items: cabling of the rotator, cabling of the

telescope interface, and physical routing of all cables.

Rotator Electronics

Setup and Cabling

You should have already attached the motor, belt, adjusted the pulley,

and installed the homing sensor and tab, limit switch, and encoder; see

Rotator

Installation for instructions. You will now attach all the

electronics for driving the rotator, measuring its position, and

communicating with allegro. If not

already mounted to the optics

box, all the parts mentioned below should

have been found in an obvious storage place, either in the 3rd floor

Bolocam storage room or near allegro.

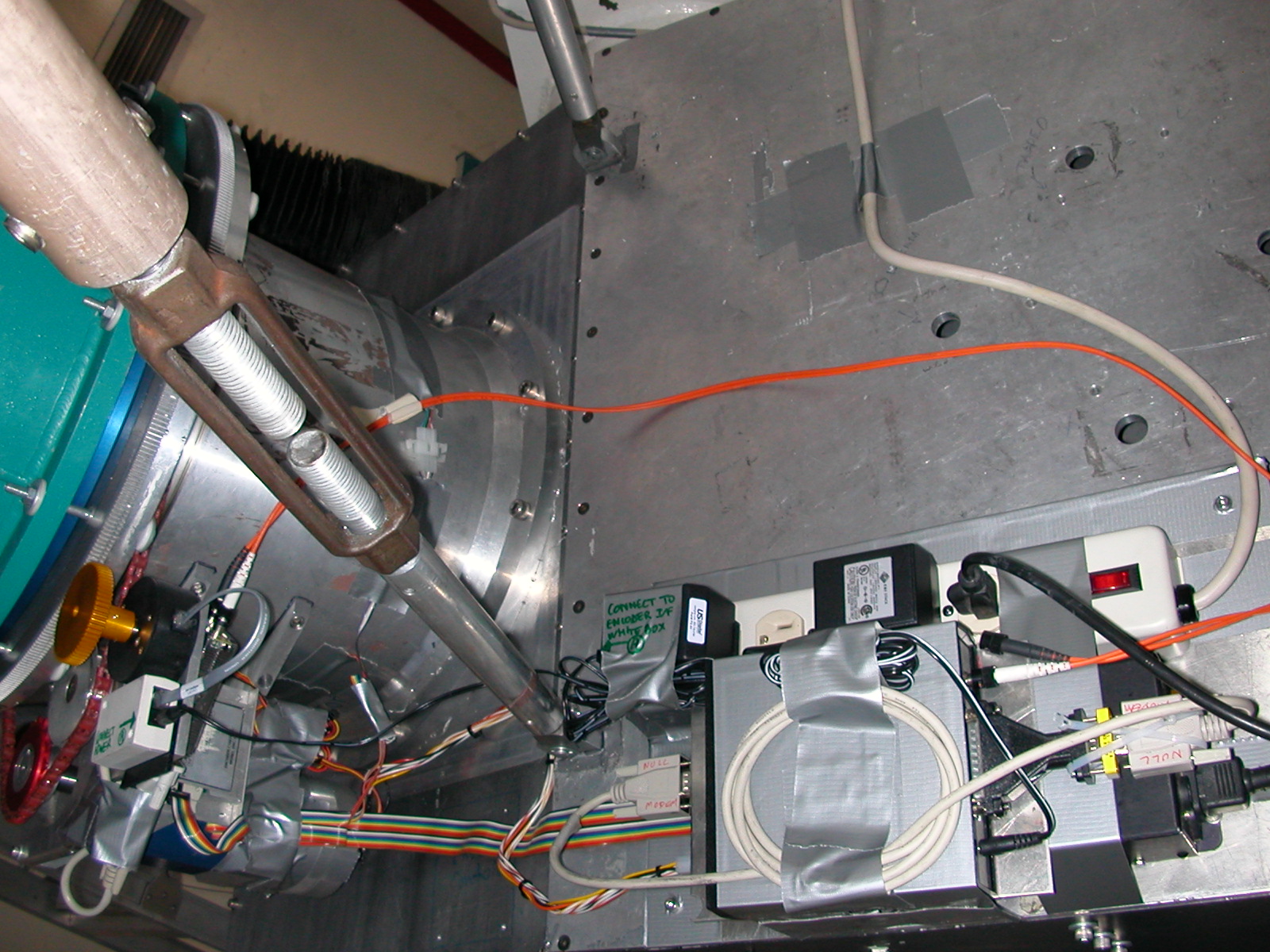

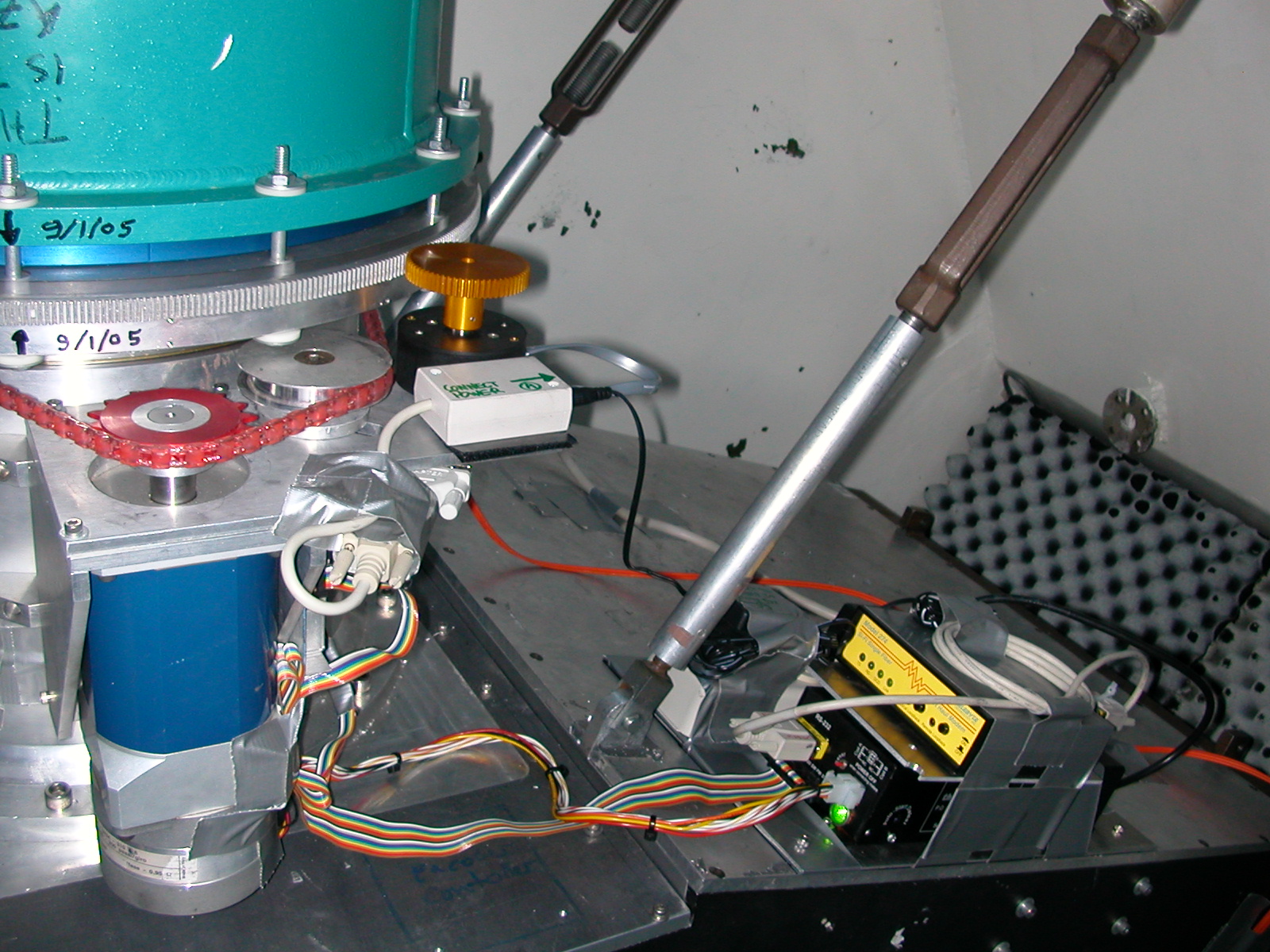

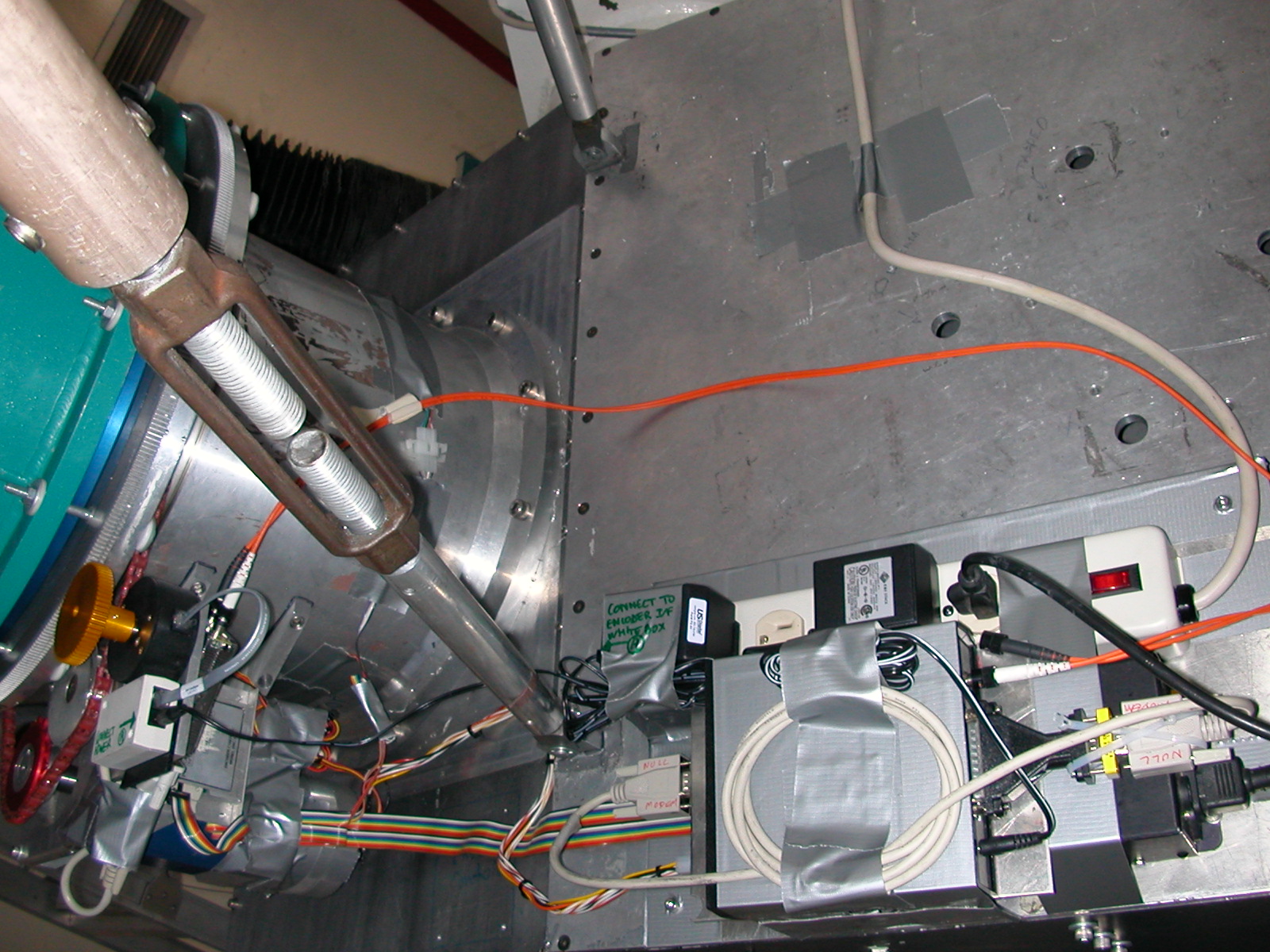

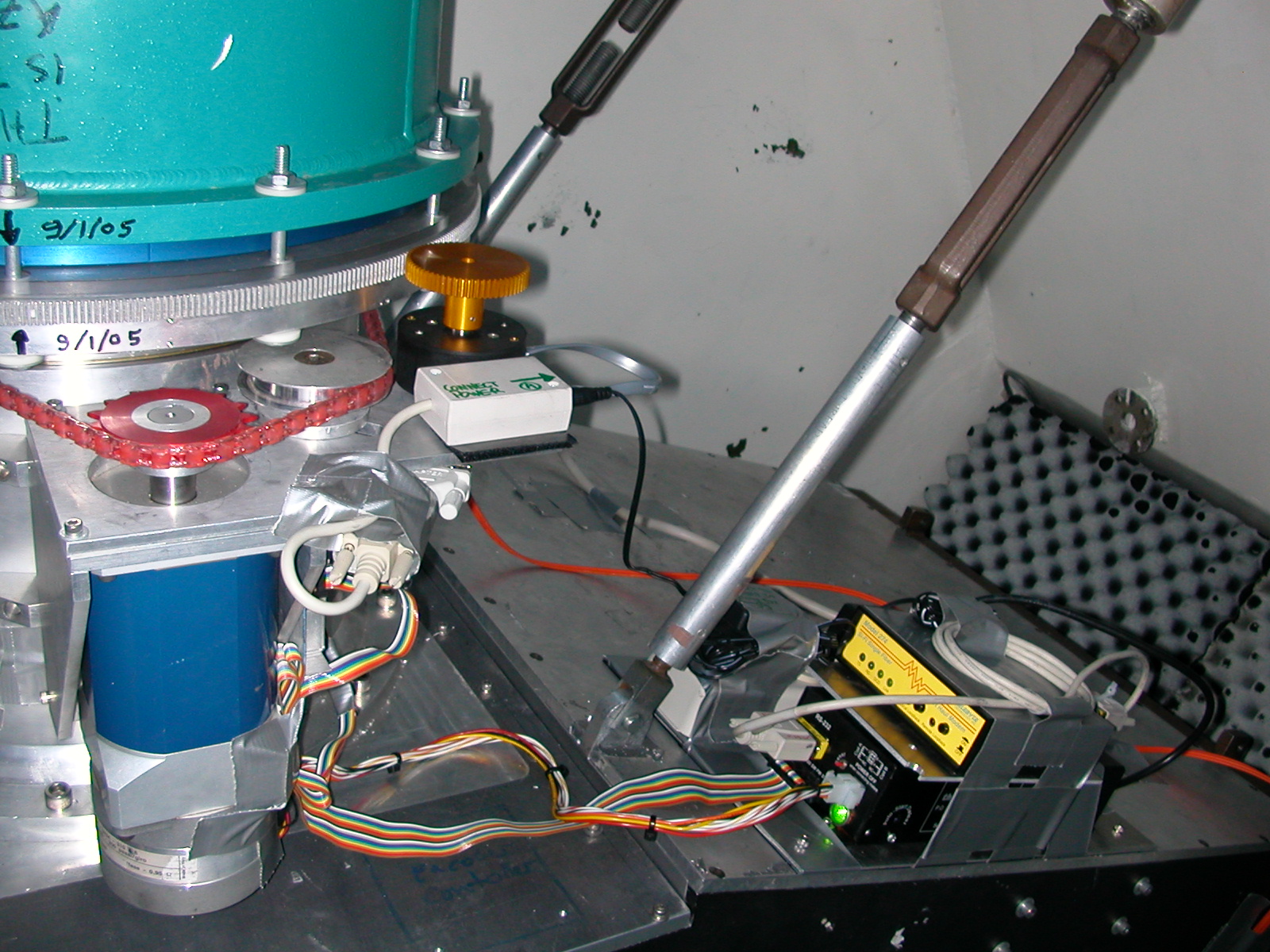

Refer to these two pictures

(double-click to get larger versions):

- On the optics box

- The rotator assembly consists in:

- the rotator motor and its power supply (SID 2.0 rectangular black box)

- the motor encoder and its controller (a squarish flat thing)

- the rotator encoder (gold gear) and its encoder (white small box)

- Limit switch, and home sensor

- The assembly is simplified by regrouping the hardware in two different blocks:

- A. Attached to the motor structure are the motor and its encoder, as well as the rotator encoder + adapter

- B. Mounted on an aluminum plate are the motor power supply, the motor encoder controller and a set of AC power outlets

- Mounting instructions (DO NOT TURN ON THE POWER BEFORE HAVING CABLED UP EVERYTHING - ESPECIALLY THE MOTOR TO ITS POWER SUPPLY):

- if not already done, mount the rotator onto the optic box. Already attached and cabled up should be the hardware defined above in block A. Screw in the aluminum plate defined above as block B (there are 4x 10-24 tapped hole marked in the optic box for this purpose).

- Connect the motor to its power supply (the motor has one cable with a white plastic connector; this is

the motor power cable and connects to an obviously matching connector

on the motor power supply)

- Connect the large ribbon cable to the motor power supply. This ribbon cable is made up of all wires on the rotator side going to a single connector plug on the motor power supply side. Again, the plug is keyed and unique, so not mistake possible.

- connect the DC power adapter connector to the rotator encoder controller (white box, featuring a phone cable)

- connect the AC power outlets to one of the dirty power outlet tapped down on the left side of the alidade platform that moves with the telescope.

- turn on the main power and the motor power supply.

- More Wiring details if needed:

- Apart from the motor power cable, the motor should have one more free cable; this is for the

motor shaft encoder. It should have a brown 4 or 6-pin Molex

connector that connects to one side of the motor encoder

controller. Note that the connector is keyed.

- The largest connector on the other end of

the ribbon cable that plugs into the motor power supply connects to the motor encoder controller. The

two remaining free wires connect to the homing sensor and limit switch;

they are keyed so there is no ambiguity.

- The encoder has its own additional wiring. There should

be a small white or beige assembly that has a telephone connector, a

DB9 RS232 connector, and a DC power adapter connector; this is called

the encoder adapter. The

encoder connects to this assembly via a special phone cord (should be

stored with the encoder). There should be a DC power adapter to

power this assembly; it should be plugged into dirty power as the motor

supply was.

- From the optics box to the computer. The motor power supply

and the encoder adapter each have DB9 RS232 ports for connecting to

allegro.

- The preferred method for connection uses optoisolators to avoid

connecting allegro to the

optics box.

- Connecting the encoder:

- Assignment, setup and cabling of the fiber-optic

isolators. These are just

directions for which isolator goes at which end and how to cable them,

wait for specific instructions below on when to connect them.

- You should find 2 Telebyte 271 fiber-optic-to-RS232

adapters, as well as some RS232 DB9-to-DB25 adapters. Do not

confuse the Telebyte 271 adapters with the Telebyte 274 fiber-optic

modems used

for the motor below. The Telebyte 271 modules simply convert the

RS232 port transmit and receive lines to fiber.

They require no outside power (they draw power from the RS232 port

connector). The fiber

adapter comes

in two flavors, which are labelled rotator and computer. Details and

settings:

- rotator end: adapter has red writing, a male

DB25 connector. The DCE/DTE switch should be set to DTE

(mnemonic: "TE" for "terminal end")

- computer

end:

adapter has blue writing, a female DB25 connector. The DCE/DTE

switch should be set to DCE (mnemonic: "CE" for "computer end")

- Each fiber adapter has two ports, labeled T and R

(transmit and receive) and also labeled B and W (for black and

white). You

should have found a spool of fiber-optic cable lying around. This

spool has two cables that each have 2 fibers, one cable each for the

motor power supply and the encoder adapter. They are labeled motor and encoder For the encoder cable, the connectors are

connected to the Telebyte 271 fiber adapters using the B and

W color code. (A given fiber has the same color connector on

both ends.) The connection scheme should be:

- rotator

end: T --> black, R--> white

- computer

end: T --> white, R--> black

- These adapters connect to their respective DB9

RS232 cables at the computer or rotator end using DB9-to-DB25

adapters. You will have to select the correct sex DB9-to-DB25

adapters at each end.

- Instructions for installing:

- Connect the rotator-end

Telebyte 271 (make sure you have the right one!) to the encoder DB9 RS232 cable and to the

rotator end of the encoder

fiber-optic cables. Remember, two fiber connections matching the

color code above.

- Run the fiber-optic cables into the control

room.

The best way to do this is to run them forward along the optics box to

the

elevation bearing, down to the alidade, under the alidade, and then

back up to the hole in the control room wall near allegro. The

allowed bend radius for the fiber is 15 cm, so be careful not to bend

or cable-tie it too tightly.

- allegro

has a multi-port RS232 card. If not

already in place, you should find a cable that has a high-density D

connector

on one end and 5 standard DB9 connectors on the other end. If it

is

not already connected to allegro,

do so now (there is only one

connector port on the back of allegro

it can mate to). Of the DB9

connectors, one is labeled motor

and one encoder. Connect

the computer side Telebyte 271

to the encoder DB9

connector, using the necessary DB9-to-DB25 adapter. Connect the computer side Telebyte 271 to the encoder fiber-optic cable, again

being sure to follow the connector color scheme. Be sure to

avoid mixing up the motor and encoder

cables and to attach the fibers using the black/white color code

correctly.

- Summary for encoder

connections:

Encoder --> phone cable

--> encoder adapter (DB9F)

--> DB9M/DB25F adapter

--> Telebyte 271 labeled rotator

(DB25M)

--> two fibers labeled encoder,

rotator side (fibers: T --> B, R --> W)

--> Telebyte 271 labeled computer

(fibers: W --> T, B --> R) (DB25F)

--> DB25M/DB9F adapter

--> computer RS232 port cable labeled P1 encoder

- Connecting the motor:

- Assignment, setup and cabling of the fiber-optic

isolators. These are just

directions for which isolator modem goes at which end and how to cable

them,

wait for specific instructions below on when to connect them.

- You should find 2 Telebyte 274 fiber-optic modems,

with RS232

ports. There should also be some leftover RS232 DB9-to-DB25

adapters. Do not

confuse the Telebyte 274 modems with the Telebyte 271 adapters used for

the encoder above. (The motor needs the Telebyte 274 modems,

which are more sophisticated than the Telebyte 271 adapters, because

the motor requires hardware flow control.) The Telebyte 274

modules multiplex all the RS232 port signals onto a single

fiber-optic. The Telebyte 274 modules have their own power

supplies (including AC/DC converters) -- make sure you have found them (but leave the Telebyte 274's powered off

until everything is connected). Make sure both Telebyte

274's have their "local loopback" and

"remote loopback" switches OFF. The Telebyte 274 modules

at the two ends are identical, but have their DIP switches set

differently, so make sure you note the rotator and computer labeling. DIP switch

settings (1 = ON, 0 = OFF):

- rotator end:

switch #

|

1

|

2

|

3

|

4

|

5

|

6

|

7 |

8

|

9

|

10

|

11

|

12

|

setting

|

1

|

0

|

0

|

0

|

0

|

0

|

0

|

1

|

0

|

1

|

1

|

0

|

- computer

end:

switch #

|

1

|

2

|

3

|

4

|

5

|

6

|

7

|

8

|

9

|

10

|

11

|

12

|

setting

|

1

|

0

|

0

|

0

|

1

|

1

|

1

|

1

|

0

|

1

|

1

|

0

|

- Each Telebyte 274 has a single fiber port.

The spool of fiber that you found above has a second cable labeled motor with two fiber lines in

it. You only need one of the

lines for the motor because the Telebyte 274 modules multiplex

all the RS232 port signals onto a single fiber. You will pick one

of the fiber lines (black or white) and connect it at both ends,

leaving the other fiber line unused.

.

- Again, the Telebyte 274 modules connect to their

respective DB9 RS232 cables at the computer or rotator end using

DB9-to-DB25

adapters. You will have to select the correct sex DB9-to-DB25

adapters at each end. The

rotator-end motor RS232 cable requires a null modem adapter between the

Telebyte 274 and the motor controller. The null modem is

DB9F on both ends and pinned out as follows:

Telebyte 274

|

1/6

|

2

|

3

|

4

|

5

|

7

|

8

|

motor

|

4

|

3

|

2

|

1/6

|

5

|

8

|

7

|

Pin 9 on both ends are NC.

- Instructions for installing:

- Connect the rotator-end

Telebyte 274 (make sure you have the right one!) to the motor DB9 RS232 cable as

instructed above (including the null

modem adapter) and to the

rotator end of the motor

fiber-optic cable. Remember, you only need one fiber connection,

the other will be left dangling.

- You presumably have already run the fiber-optic

cables into the control

room.

- You presumably have already connected the

multi-port RS232 cable to allegro.

Connect

the computer side Telebyte 274

to the motor DB9

connector, using the necessary DB9-to-DB25 adapter (no null-modem

adapter needed at this end). Connect the computer side Telebyte 274 to the motor fiber-optic cable, using the

same color connector as was used at the rotator end. This will

leave one of the fiber optic lines unused. Be sure to use the

same color connector!

- When you have connected both ends, power on both

Telebyte 274 modules. You should see the DCD and Link lights come on almost

immediately. The TD and RD (transmit and receive) lights

will remain off until you issue a command to the rotator. If you

do not have DCD and Link lights, there may be a problem with the fiber,

power adapters, or DIP switch settings. Check everything, try

substituting a different fiber-optic line (you can disconnect and

temporarily use one of the encoder fiber-optic lines, for

example). If you don't get DCD and Link lights, you simply will

not be able to communicate with the motor.

- Summary for motor

connections:

Black motor controller --> gender changer DB9 M/M

--> null modem

DB9 F/F

--> gender changer DB9 M/M

--> DB9F/DB25M adapter

-->

Telebyte 274 labeled rotator

(DB25F)

--> fiber optic labeled motor,

rotator side white connector

--> fiber optic labeled motor,

computer side white connector

--> Telebyte 274 (DB25F)

--> DB25M/DB9F adapter

--> computer

RS232 port cable labeled P0 motor

- If you don't want to use the optoisolators, things are simpler.

- For the motor, there is a long black RS232 cable (DB9 on

both ends). This can be connected directly from the DB9 on the

motor power supply to the motor RS232 port cable at allegro.

- For the encoder, you should bring the encoder adapter inside

the control room and connect it directly to the encoder RS232 port

cable from allegro.

The DC power supply will of course also come

inside. The telephone cable from the encoder adapter to the

encoder should be long enough to go out from the control room to the

dewar.

- Regardless of how you have done the cabling between allegro and

the optics box, tape or tie down all loose cables. Be careful

that you have routed the cables such that they are out of the way and

will not be damaged by telescope motion. This is shown here, here, and here; the fibers come through the

hole in the wall near allegro,

drop down below the alidade, and then

come up the elevation plate and loop over to the optics box.

- END OF RUN: You do not

need to disassemble everything you have just assembled. You will

of course have to disconnect and bundle up the fiber optic. But

you may leave all items on the optics box there, and similarly in the

computer room. But, double-bag

the rotator encoder and put a tarp over the optics box to protect these

pieces of electronics from the weather. The rotator encoder is

especially sensitive to any kind of water damage. Each one costs

$300, we do not want to have to replace it every run.

Telescope Interface

Cabling

There are multiple BNC cables that connect between the telescope

computer, allegro, and

the DAS. A schematic of the cable

connections is provided here.

Some explanation is necessary:

- The Digital I/O on Allegro

refers to a small metal box with 16 BNC connectors that provides

isolated digital inputs and outputs for allegro.

- The Blue

Box and Silver Box

refer to boxes in the AOS

lab that the telescope computer uses for digital outputs (blue) and

inputs (silver). They are at the far right end of the wall of

racks.

- The DAS TTL Input Board

is the optoisolator board in the DAS rack referred to on the Electronics page.

- The Chopper Encoder Monitor comes

from the analog output of the secondary chopper encoder, runs out

through a hole in the sidecab (in the upper left above the

chopper-tuning oscilloscope) and up to the 3rd floor. The chopper

encoder signal MUST be

digitized in order to analyze chopped data! See the Electronics

page for where it should

connect to.

The meaning of the signals is not important now; see the discussion on

the Data Acquisition,

Rotator Control, Data Handling page for details.

These BNC cables should already be in place and connected at the

telescope computer and allegro.

They will be labeled by their

signal names at each end. If any are missing, you will have to

run new ones. If they are in place and not connected, go ahead

and connect them to the channels at each point as the diagram

indicates. The connections at the DAS rack are given on the Electronics page.

The digital I/O box at allegro

connects to allegro via a

simple

DB37/DB37 cable to a unique port on the back of allegro. Make

sure the digital I/O box power switch is on (it draws power from

allegro).

The best way to test the connections is simple to do fake observation

and see if everything works. If you find possible problems, you

can tee in DMMs on the various BNCs at the digital I/O box and also

monitor the signals going to the DAS via the DAS. All the signals

are TTL logic levels; logic 0 is between 0V and 0.5V and logic 1 is

around 3V I think.

If you find deeper problems (the signals are not being asserted by the

telescope or the digital I/O box as they should, the signals make it to

the DAS rack but the optoisolator board fails to transmit them to the

multiplexer), you will probably have to call an expert. If you

are feeling brave, schematics of the digital I/O box and the

optoisolator board can found in the Bolocam big black binder or on the Bolocam internal

web page.

Physical Routing of

Cables

All these cables have to be run around in ways that keep them out of

the way and allow dewar and telescope motion.

The most painful to deal with are all the cables that go between the

e-box and the lockin/DAS and fridge racks. This consists of the

e-box power cable, the fridge and aux thermometry cables, the GRT

readout cable, the bias spider cable, and the 6 monster

preamp-to-lockin cables. The usual way we do this is to route the

cables from the dewar up to the hex plate, over to the elevation

bearing by the side cab, on top of the side cab, and to the

racks. It is simplest if you first route the bundle consisting of

the 6 monster cables and the bias spider. Cable ties should be

used to tie these cables to the various eyeholes along the way.

At the dewar, the cables should be cable-tied to the through holes in

the middle flange so that their weight is not resting on their

connectors to the e-box. Enough slack between the hex plate and

the dewar must be provided to allow rotation of the dewar. Some

pictures serve to illustrate:

- Views of the cabling at the dewar: from left,

from right, from back.

- View of the cables going

up

to the

hex plate.

- View of the cables coming

onto the sidecab.

Take up the slack in the monster cables on top of the side cab.

Once these guys have been run, you can run the GRT cable, the e-box

power cable, and the fridge and aux thermometry cables on top of them.

The BNC cables carrying the TTL signals are routed primarily on cable

trays. The cables come out from the blue and silver boxes in the

AOS rack and run to the cable tray above the rack. The cables

going to allegro will

branch off into a different tray running to the

control room, staying in cable trays until they drop down to the floor

near allegro. The

cables going up to the DAS run through a hole

in the AOS lab wall (the same hole used for cables going to the

sidecab) and then run up between the AOS lab wall and the sidecab up to

the 3rd floor.

As mentioned above, the chopper encoder cable runs out from the hole in

the sidecab wall up to the 3rd floor.

Finally, once you are all cabled up,

watch the cables as you run the telescope from ZA = 4 degrees to ZA =

65 degrees (or so) to make sure nothing will get damaged during normal

observing.

Electronics Setup

There's not much to this once you are cabled up; for your first night

pointing study, you just want to make sure you have a vaguely

reasonable bias and can see astronomical signals. Do the

following:

- Make sure the bias board is properly configured for AC bias

mode;

see the Electronics page for details.

- If you are using the old Rev. 2 bias board then

set the AC bias amplitude so you get a DC lockin voltage of

about

3V for 1.1 mm observations or about 6V for 2.1 mm observations.

The voltage will depend on what tau is, but be assured that much less

than 2V is too low for 1.1 mm and less than 5V is too low for 2.1 mm.

- If you are using the Rev. 3 bias board then

set the AC bias amplitude so you get a DC lockin voltage of

about

2.5V for 1.1 mm observations or about 3.7V for 2.1 mm observations.

- Make sure you are getting sensible noise; the DC lockin signals

should be bit limited, the AC lockin signals typically have 50-200 mV

of noise.

Revision History

- 2004/01/30 SG

First version

- 2004/01/31 SG

Lots more stuff

- 2004/04/26 SG

Add updated TTL block diagram link.

- 2004/05/13 SG

Add pictures.

- 2004/12/13 SG

Add lots more detail on attaching fiber-optic adapters for rotator,

include new Telebyte 274 modems.

- 2005/01/25 SG

Add instructions to double-bag encoder and put tarp on optics box after

run.

- 2005/06/06 SG

Minor corrections.

- 2005/09/12 PR

update for new rotator hardware settings

- 2009/10/27 JS

add instructions for bias level of Rev. 3 board

Questions or

comments?

Contact the Bolocam support person.